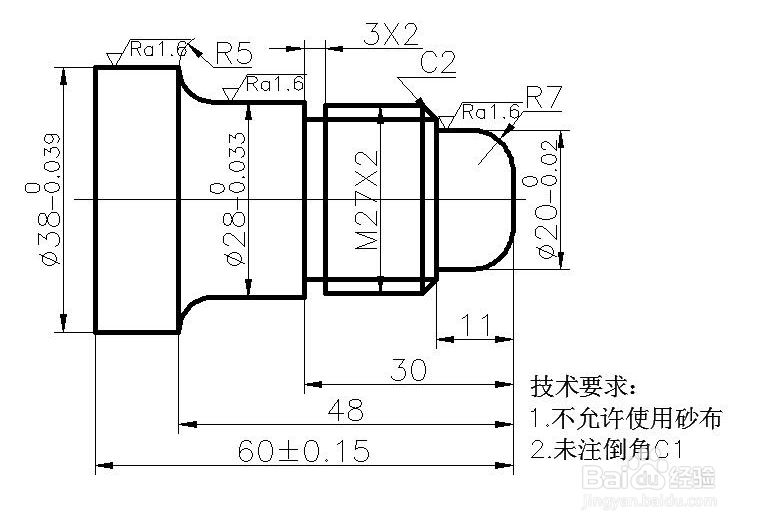

1、零件图纸工艺分析该零件表面由圆柱、顺圆弧、逆圆弧及螺纹等表面组成。其中多个直径尺寸有较严的尺寸精度和表面粗糙度等要求。尺寸标注完整,轮廓描述清楚。零件材料为铝,无热处理和硬度要求。

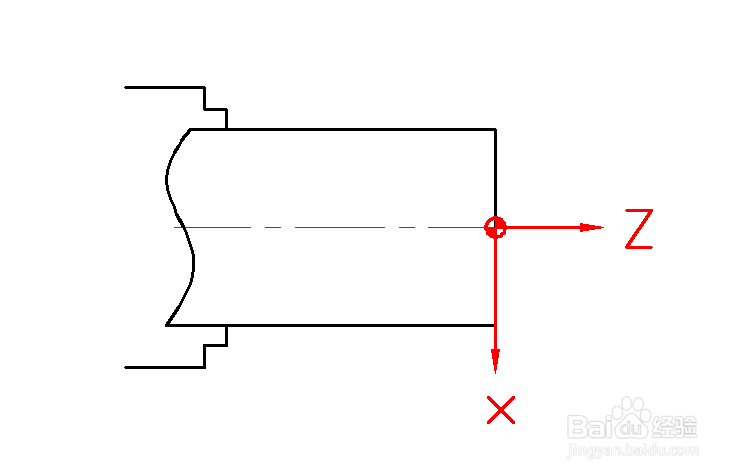

2、装夹方案以毛坯右端面与回转中心交点为原点建立工件坐标系,左端采用三爪自定心卡盘装夹,毛坯伸出长度80(伸出长度要大于切断长度)

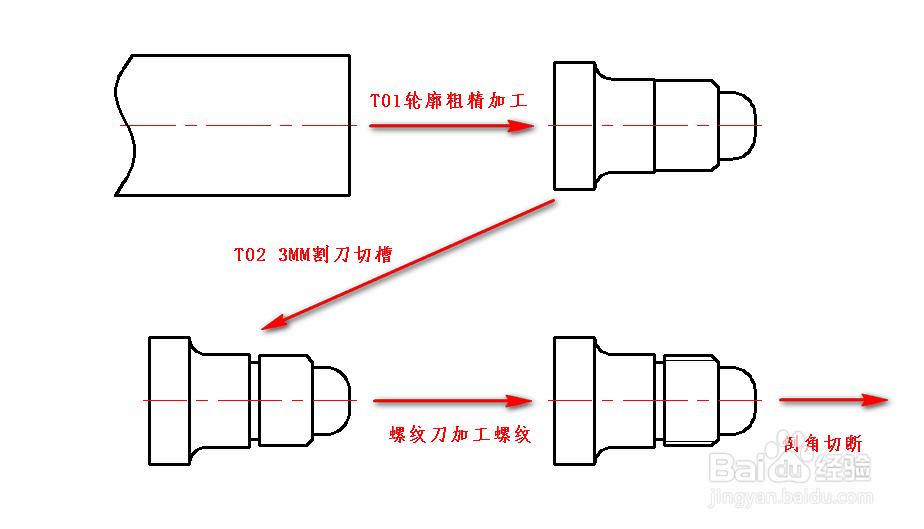

3、加工路线1、外圆车刀T01用G71进行轮廓粗加工,G70进行精加工2、3MM割刀T02切槽至尺寸要求3、60度螺纹刀T03用G92加工螺纹至尺寸要求4、T02 3mm割刀倒角及切断5、调头,找正夹紧,平端面至尺寸要求!

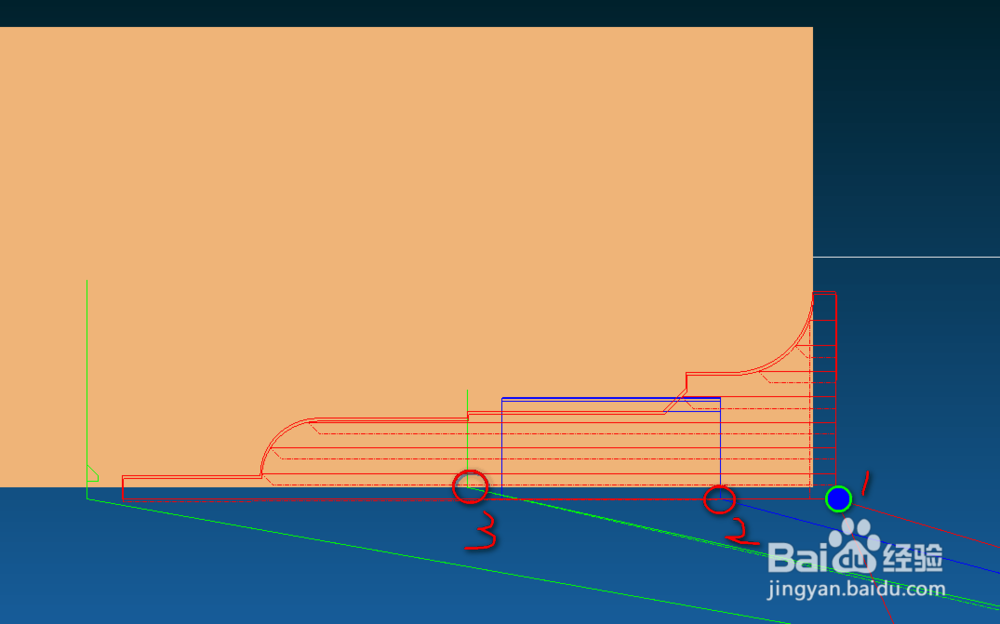

4、加工路线,红色为外圆粗精车,绿色切槽及切断,蓝色螺纹

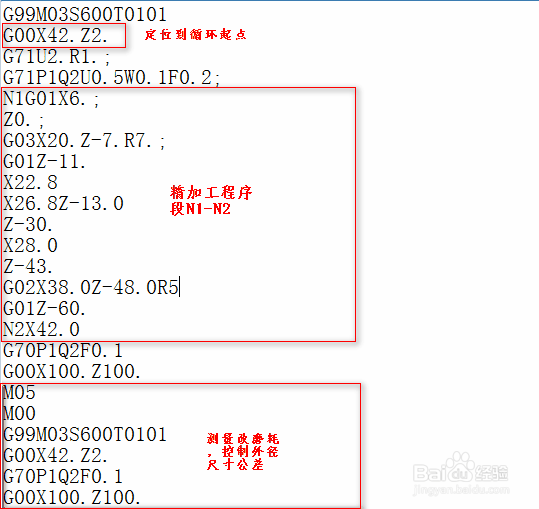

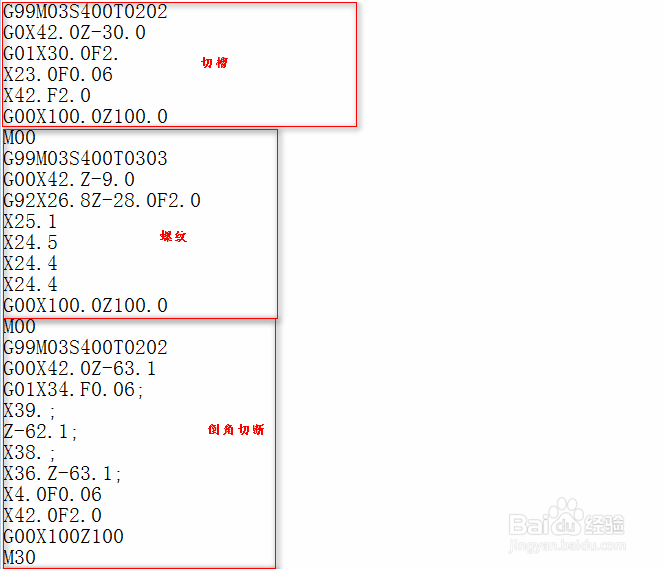

5、程序解析

6、G99M03S600T0101G01X42.Z2.F2. //G00X42.Z2.;G71U2.R1.;G71P1Q2U0.5W0.0F0.2; N1G01X6.;Z0.;G03X20.Z-7.R7.;G01Z-11.X22.8X26.8Z-13.0Z-30.X28.0Z-43.G02X38.0Z-48.0R5G01Z-60.N2X42.0G70P1Q2S800F0.1G00X100.Z100.M05M00G99M03S600T0101G01X42.Z2.F2. //G00 X42.Z2.G70P1Q2S800F0.1G00X100.Z100.M05M00G99M03S400T0202G01X42.0Z-30.0F2.0X30.0 F0.06X23.0F0.06X42.F2.0G00X100.0Z100.0M05M00G99M03S400T0303G01X42.Z-9.0F2.0G92X25.9Z-28.0F2.0 //G92中F为螺距值X25.3X24.7X24.4X24.4G00X100.0Z100.0M05M00G99M03S400T0202G01X42.0Z-63.1F2.0G01X34.F0.06;X42.;Z-62.1;X38.;X36.Z-63.1;X4.0F0.06X42.0F2.0G00X100.Z100.M30